Introduction to Pile Foundations

Pile foundations are deep foundation systems used when surface soils cannot adequately support structural loads. As structural engineers at Ultra Engineering Services, we specialize in designing and implementing pile foundation solutions for challenging soil conditions across Pakistan.

Pile foundations transfer structural loads through weak, compressible strata or water onto stronger, more compact soil or rock layers at depth. These long, slender structural elements can be made of concrete, steel, or timber and are either driven or drilled into the ground.

When are Pile Foundations Used?

In our projects across Peshawar, Islamabad, and other regions, we recommend pile foundations when:

- Surface soil has low bearing capacity

- Expansive or collapsible soils are present

- Structures face significant uplift or lateral forces

- There's risk of scour from flowing water

- Vibration from pile driving won't affect nearby structures

Types of Pile Foundations

Based on our extensive experience at Ultra Engineering Services, we classify pile foundations by their load transfer mechanism and construction method.

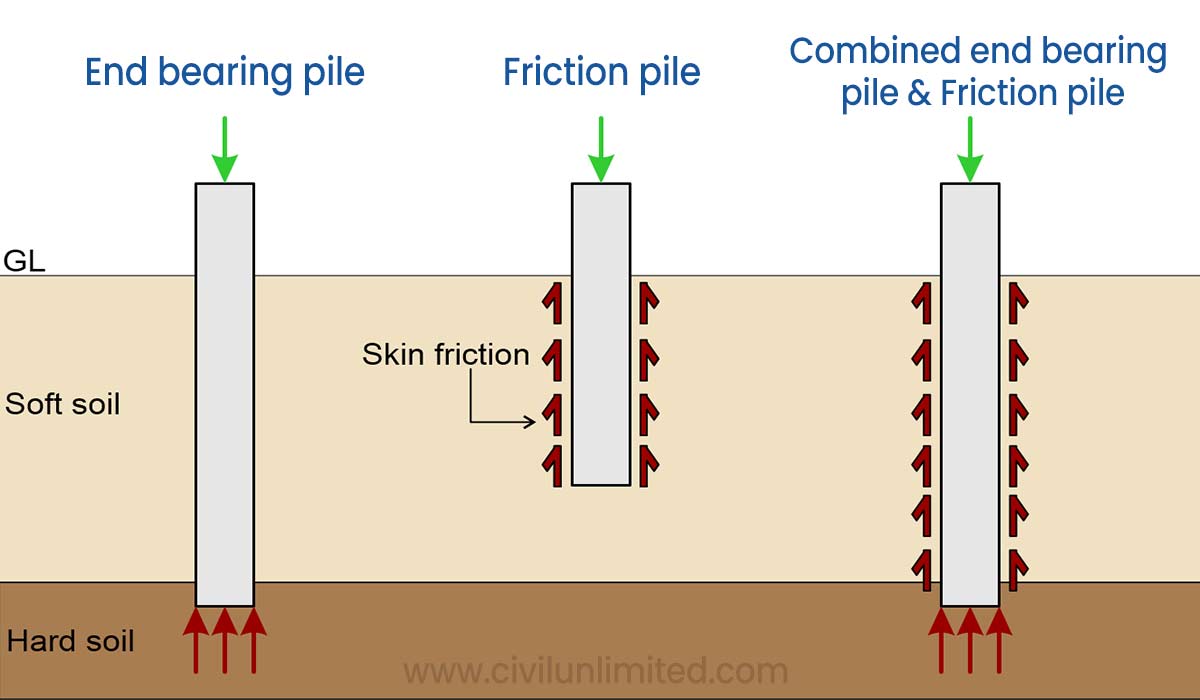

By Load Transfer Mechanism

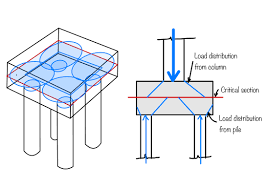

End Bearing Piles

These piles transfer load to a firm stratum (rock or dense soil) at their base. They act like columns, with capacity primarily from end bearing at the tip.

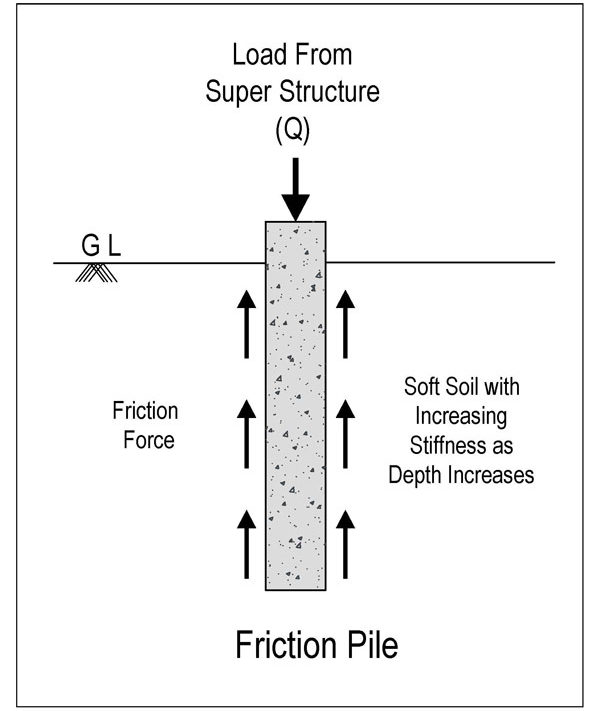

Friction Piles

These develop load capacity through skin friction between the pile surface and surrounding soil. Used when no strong layer exists at reasonable depth.

Combination Piles

Most piles combine both end bearing and friction resistance. Our designs optimize this combination based on soil conditions.

By Construction Method

| Type | Advantages | Disadvantages | Our Projects |

|---|---|---|---|

| Driven Piles (Precast concrete, steel, timber) | High capacity, immediate load transfer, quality control | Noise/vibration, displacement may damage adjacent structures | MGH Commercial Complex, Jhelum |

| Bored Piles (Cast-in-situ) | Minimal vibration, large diameters possible, can penetrate hard layers | Soil collapse risk, concrete quality control, slower installation | 091 Shopping Mall, Peshawar |

| Auger Cast Piles | Continuous support, minimal vibration, good in loose soils | Limited depth, quality depends on operator skill | LAL Plaza, Timergara |

Pile Materials

At Ultra Engineering Services, we select pile materials based on project requirements, soil conditions, and cost considerations:

Reinforced Concrete Piles

Our most common choice for major projects in Pakistan. We use both precast and cast-in-situ concrete piles depending on site conditions.

Steel Piles

We specify steel H-piles or pipe piles when high capacity is needed in limited space or when driving through dense layers is required.

Timber Piles

For temporary structures or light loads in suitable soil conditions, we may recommend treated timber piles as a cost-effective solution.

Pile Capacity Calculation

Qu = Qs + Qb

Where:

Qu = Ultimate pile capacity

Qs = Skin friction resistance

Qb = End bearing resistance

Pile Foundation Design Process

Our structural engineering team follows this rigorous design process for pile foundations:

- Geotechnical Investigation: We conduct thorough soil testing including SPT, CPT, and lab tests to characterize soil properties.

- Load Analysis: We calculate all structural loads including dead, live, wind, and seismic loads.

- Pile Type Selection: Based on soil conditions and loads, we select the optimal pile type and material.

- Capacity Calculations: Using methods from ACI 543, we calculate individual and group pile capacities.

- Settlement Analysis: We estimate short-term and long-term settlements to ensure serviceability.

- Structural Design: We design pile caps and connections using ETABS and SAFE software.

- Construction Planning: We develop installation procedures and quality control measures.

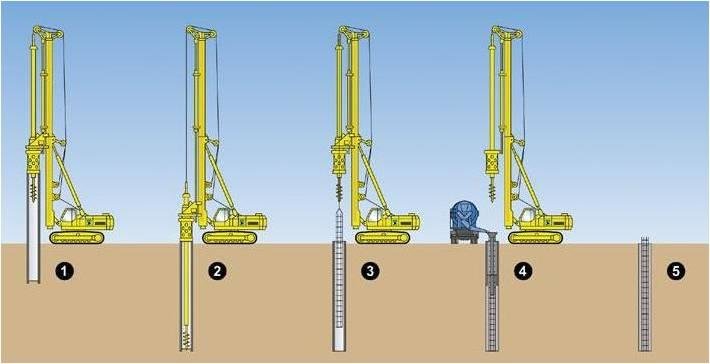

Construction Techniques

Our field experience across Pakistan has refined our construction methodologies:

Driven Pile Installation

- We use hydraulic hammers for most projects, selecting energy appropriate for pile size

- Drive criteria are established based on wave equation analysis

- We monitor blow counts and penetration rates to verify design assumptions

Bored Pile Construction

- For our projects in Peshawar and surrounding areas, we typically use rotary drilling rigs

- Bentonite or polymer slurry is used when needed to stabilize boreholes

- We conduct thorough cleaning of the borehole base before concreting

- Tremie pipes ensure proper concrete placement without segregation

Quality Control Measures

At Ultra Engineering Services, we implement strict QC protocols:

- Pile load testing (static and dynamic)

- Integrity testing (PIT, crosshole sonic logging)

- Continuous monitoring of concrete pours

- Documentation of all installation parameters

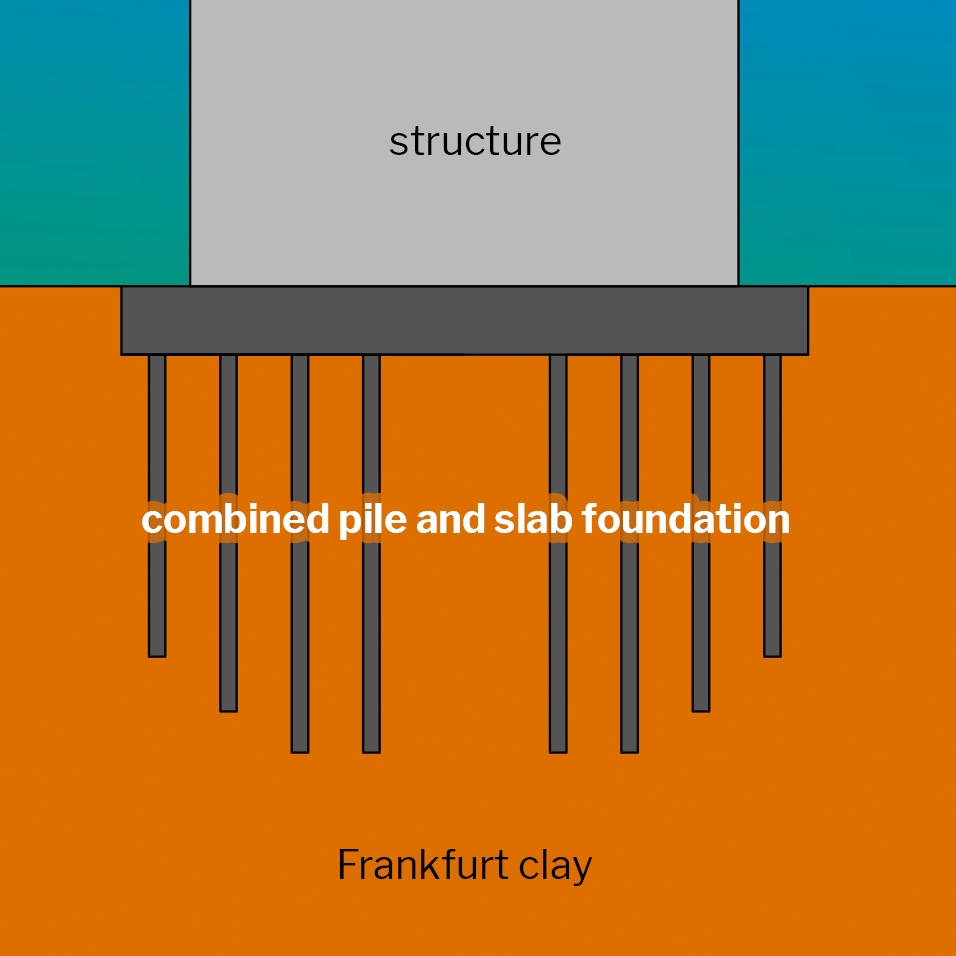

Case Study: 091 Shopping Mall, Peshawar

Our work on the 15-story 091 Shopping Mall demonstrates our pile foundation expertise:

- Challenge: Soft alluvial soils with high water table

- Solution: 900mm diameter bored piles to bedrock at 35m depth

- Design: Combination friction and end bearing piles with 2500kN working load

- Innovation: Use of polymer slurry to stabilize boreholes in sandy strata

- Result: Completed with <2mm settlement after 2 years of monitoring

Advantages of Pile Foundations

Based on our project experience, key benefits include:

Deep Support

Can reach stable soil layers far below weak surface soils, essential in Pakistan's varied geology.

High Capacity

Our designed piles regularly support loads exceeding 5000kN for major structures.

Versatility

Adaptable to almost all soil conditions encountered in our regional projects.

Conclusion

Pile foundations are an essential solution for modern construction in Pakistan's challenging soil conditions. At Ultra Engineering Services, we combine technical expertise with local experience to deliver optimized pile foundation solutions.

Our approach integrates thorough geotechnical understanding, advanced analysis methods, and rigorous quality control to ensure long-term performance. As construction challenges grow with taller buildings and more complex sites, we continue to innovate with techniques like post-grouting and energy pile systems.

For your next project, consult with our team of pile foundation specialists to develop the most efficient and reliable foundation solution.